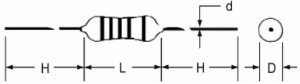

金屬皮膜電阻 (FMF)

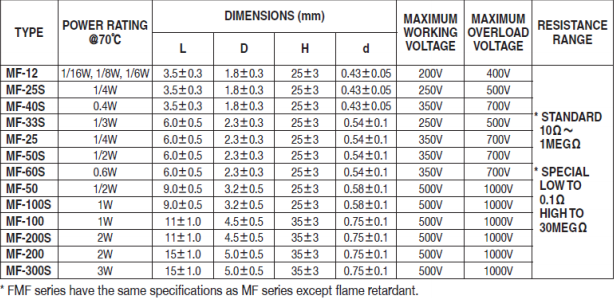

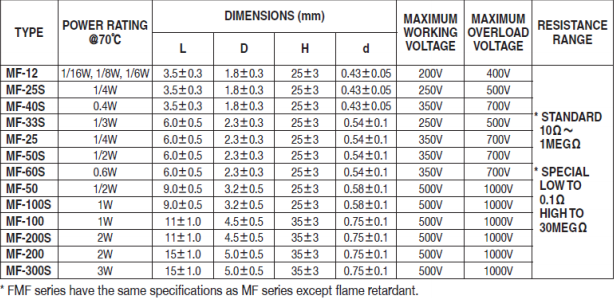

TYPE: FMF-12 , FMF-25S, FMF-40S , FMF-33S , FMF-25 , FMF-50S , FMF-60S , FMF-50 , FMF-100S , FMF-100 , FMF-200S , FMF-200 , FMF-300S

METAL FILM FIXED RESISTOR

FMF (FLAME-PROOF COATING TYPE)

♦INTRODUCTION

Flame-proof metal film resistors are coated with layers of non-flame lacquer which is resistant to 800℃ high temperature and without causing crack, breakage, or even a fire hazard. SYNTON-TECH’s FMF series are designed to replace metal oxide film resistors and wire wound resistors when small size is needed.

♦FEATURES

-Met American military specification MIL-R-10509F!

-Very low currect noise!

-Board selection of temperature coefficient: ±100ppm, ±50ppm, ±25ppm, ±15ppm, ±10ppm/℃

-Tolerance available: ±5%, ±2%, ±1%, ±0.5%, ±0.25%, ±0.1%, ±0.05%, ±0.01%

-Voltage available: 1/16W, 1/8W, 1/6W, 1/3W, 1/4W, 0.4W, 1/2W, 0.6W, 1W, 2W, 3W

-Major applications are switching power supplies, communication equipments, monitors, testing meters.

♦SPECIFICATIONS

To fill the function gap of carbon film fixed resistors, metal oxide film resistors or wirewound resistors.

The resistive element is a high contests of AL203 ceramic rod on which a thin film of Ni/Cr alloy is deposited by vacuum sputtering system. Then contact caps are pressed onto the ends of the rod and a helical groove cut through the film to give the required resistance value.

To fill the function gap of carbon film fixed resistor, metal oxide film resistor film resistor or wirewound resistors. The resistive element is high contests of AL203 ceramic rod on which a thin film of Ni/Cr alloy is deposited by vacuum sputtering system. Then contact caps are pressed onto the rod and a helical grove cut through the film to give the required resistance value.

METAL FILM FIXED RESISTOR

FMF (FLAME-PROOF COATING TYPE)

♦INTRODUCTION

Flame-proof metal film resistors are coated with layers of non-flame lacquer which is resistant to 800℃ high temperature and without causing crack, breakage, or even a fire hazard. SYNTON-TECH’s FMF series are designed to replace metal oxide film resistors and wire wound resistors when small size is needed.

♦FEATURES

-Met American military specification MIL-R-10509F!

-Very low currect noise!

-Board selection of temperature coefficient: ±100ppm, ±50ppm, ±25ppm, ±15ppm, ±10ppm/℃

-Tolerance available: ±5%, ±2%, ±1%, ±0.5%, ±0.25%, ±0.1%, ±0.05%, ±0.01%

-Voltage available: 1/16W, 1/8W, 1/6W, 1/3W, 1/4W, 0.4W, 1/2W, 0.6W, 1W, 2W, 3W

-Major applications are switching power supplies, communication equipments, monitors, testing meters.

♦SPECIFICATIONS

To fill the function gap of carbon film fixed resistors, metal oxide film resistors or wirewound resistors.

The resistive element is a high contests of AL203 ceramic rod on which a thin film of Ni/Cr alloy is deposited by vacuum sputtering system. Then contact caps are pressed onto the ends of the rod and a helical groove cut through the film to give the required resistance value.

To fill the function gap of carbon film fixed resistor, metal oxide film resistor film resistor or wirewound resistors. The resistive element is high contests of AL203 ceramic rod on which a thin film of Ni/Cr alloy is deposited by vacuum sputtering system. Then contact caps are pressed onto the rod and a helical grove cut through the film to give the required resistance value.